NEXT-LEVEL WAREHOUSE DESIGN

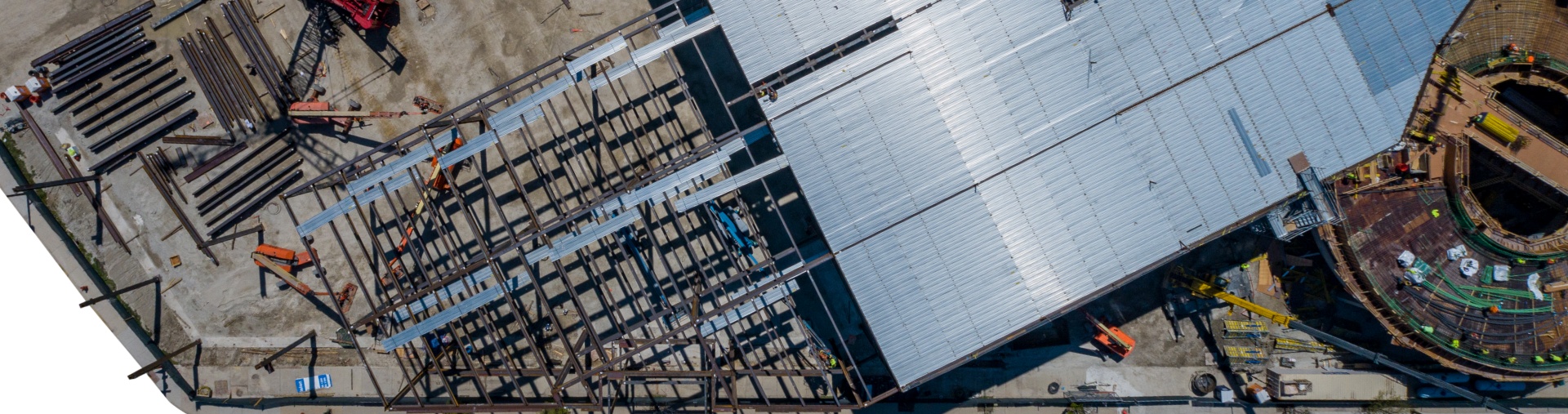

It will be hard for passersby not to notice the massive 1.2 million-square-foot, multi-story warehouse on 11.5 acres. When complete, the building will include two warehouse levels where full-size trucks can enter to load and unload goods, as well as two mezzanines. The roof will feature parking for cars that can also be used as a truck court, a unique feature for this type of building, and a pedestrian bridge will connect to a separate parking garage.

鈥淚t鈥檚 a challenge to take that truck court up to the roof level,鈥� Heeringa says. 鈥淭hat became as big of a challenge as the warehouse because the loads are high and the spans are long.鈥�

Located just two miles from the city鈥檚 center鈥攁 dynamic neighborhood that mixes residential, business, entertainment, and retail properties鈥攖he building offers unparalleled access to the largest concentration of consumers and companies in the region. The building鈥檚 owner, the structural team from DCI Engineers, general contractor The Walsh Group, project architect Ware Malcomb, and structural steel fabricator Lyndon Steel collaborated to make this project a success.

NOT YOUR TYPICAL DISTRIBUTION WAREHOUSE

What makes this project unique is that trucks can load and unload goods on an elevated floor (in this case the second floor), which is designed to maximize usage of the warehouse, Heeringa says. 鈥淣ormally with distribution warehouses, all the rack loading is on the grade level,鈥� he says. 鈥淎nytime you have an elevated warehouse floor, the loads are very high. You need to design for that as well as deflection criteria.鈥�

He says the second floor needs to accommodate a racking system to store shipments, plus the ability to operate forklifts. That can pose design challenges because the second floor needs to handle the 鈥淗S-20鈥� (highway safety) loading requirements for 18-wheelers while having enough space for a large turning radius.

Another challenging aspect of the project is that its design was seismically controlled. This required buckling-restrained braces (BRBs) to be used as part of the lateral system, of which the DCI Engineers team believes to be the first usage of BRBs in the city.

Due to the heavy loads imparted by the rooftop parking, elevated warehouse storage, and lateral system, the design and fabrication team needed a unique solution to keep the weight of the framing system down. According to DCI Engineers and Lyndon Steel, Yabo亚博集团官方网站鈥檚 Aeos鈥擜STM A913 high strength structural steel鈥攚as the clear choice to reduce tonnage while supporting the required loading conditions.